A Comprehensive Overview to Comprehending Litho Printing Strategies

The globe of litho printing, a strategy originating from the late 18th century, is a fascinating blend of history, art, scientific research and innovation. Stay with us as we trip right into the exciting realm of litho printing.

The Historic Advancement of Litho Printing

The historic trajectory of litho printing, a critical advancement in the world of interaction, is a captivating story of human resourcefulness. The procedure progressed with the arrival of the rotating press, which considerably boosted productivity. Each phase of litho printing's development showcases mankind's unrelenting quest of effectiveness and top quality in aesthetic communication.

Translating the Scientific Research Behind Litho Printing Inks

Progressing in the exploration of litho printing techniques, the focus now moves to the scientific research behind litho printing inks. The make-up of these inks, their drying procedure, and color mixing methods develop the backbone of this complex art type. Comprehending these elements is crucial to mastering the craft and accomplishing the desired print outcomes.

Make-up of Litho Inks

In lithographic printing, the fundamental role of litho inks can not be overemphasized. Pigments, the color-providing elements, are finely ground particles put on hold in the lorry, a liquid that brings the pigment onto the printing surface area. Each element plays a critical component in the final print's high quality, making the specific formula of litho inks an intricate scientific research.

Ink Drying Process

From the composition of litho inks, interest transforms to the remarkable procedure of ink drying out. The drying out procedure is essential, as it impacts the final print's top quality and durability. 2 primary techniques are used in litho printing: oxidative drying and absorption. Oxidative drying includes the ink responding with oxygen in the air to form a tough, dry film. This method supplies a resilient coating, yet can be slower contrasted to absorption. Absorption, on the various other hand, includes the ink seeping right into the paper fibers, which is a much faster process however can result in much less dynamic shades. The choice in between these methods depends on aspects such as print rate needs, the paper kind used, and the wanted surface.

Shade Mixing Techniques

While the drying process plays a crucial function in litho printing, the science of shade mixing techniques holds equivalent importance. The science behind litho printing inks likewise takes right into account the openness of the ink, which affects how shades overlay and mix.

The Art and Design Elements in Litho Printing

Litho printing breathes life right into art and style through its unique aspects. The process entails creating a picture on a lithographic limestone plate or metal plate with a smooth surface. The photo is after that printed onto a tool, normally paper, by transferring the ink from the plate. What collections litho printing apart is its capability to replicate complex layouts with high fidelity, making the output practically similar to the original artwork. This is attained through using various line strategies such as stippling, hatching, and cross-hatching, which enable a variety of tonal impacts. Litho printing suits a variety of shades, making it possible for musicians to develop lively and dynamic prints. This combination of precision and adaptability makes litho printing a recommended option for several musicians and developers.

Modern Applications of Litho Printing Methods

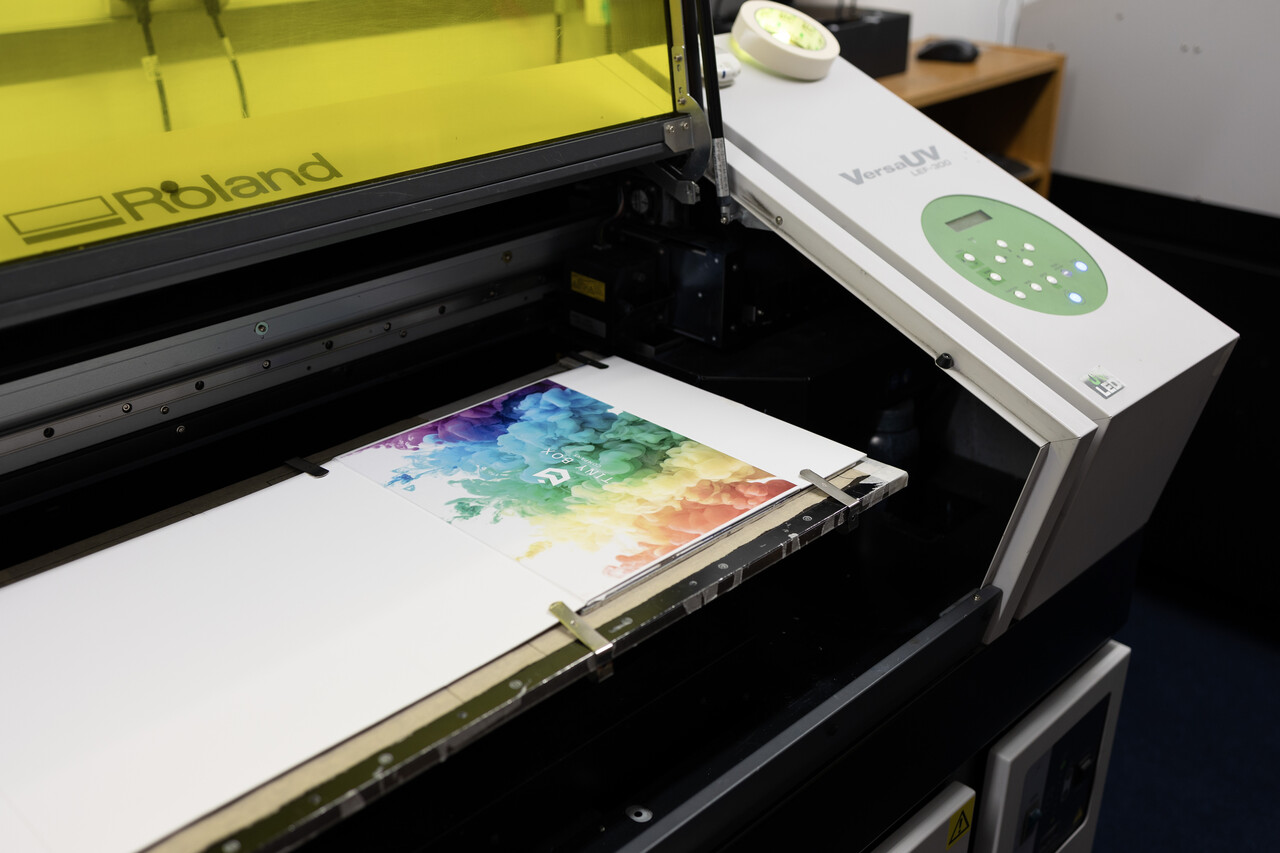

Litho printing strategies have discovered considerable usage in the contemporary commercial industry. Its impact and importance remain to expand with the development of brand-new innovations and innovations in the field. This section will certainly check out these contemporary applications and the transformative function they play in the printing industry.

Industrial Litho Printing Utilizes

Litho printing stays a crucial part of the commercial field. High-volume printing jobs, such as the production of publications, newspapers, and product packaging, rely on litho printing for its capability to provide superior picture top quality and price efficiency. Litho printing also gives a wide color range, exceptional to that of digital printing.

Advancements in Litho Printing

Pushing the borders of conventional strategies, modern innovations have fueled a host of technologies in litho printing. These breakthroughs have not only boosted the top quality and performance of litho prints yet also expanded its application extent. One prominent advancement is digital litho printing, which incorporates the merits of electronic technology with litho's high-quality result. This hybrid model supplies faster configuration times, lowered waste, and allows on-demand printing. Another remarkable innovation is see this site the intro of eco friendly inks. These inks, made from vegetable or soy-based solutions, have dramatically lowered the sector's ecological influence. litho printing. Furthermore, the development of advanced plate modern technology has structured the printing process, resulting in sharper pictures and boosted color fidelity. These innovations emphasize the enduring importance of litho printing in the modern world.

Discovering the Refine of Litho Printing: Action by Action

Difficulties and Solutions in Contemporary Litho Printing

Despite the precision and custom that litho printing happily promotes, it is not without its collection of contemporary obstacles. The most common concerns include the high first configuration cost, difficulty in printing variable information, and ecological concerns due to chemical usage. Solutions are arising as modern technology progresses. Digital litho printing permits cost-efficient short runs and very easy customization, dealing with the concern of variable data. Environmentally-friendly inks and much safer plate-making procedures mitigate ecological problems. In addition, developments in automation have actually decreased labor expenses, even more equalizing the lithography process. Thus, while there are useful source challenges, the litho printing sector is proactively adapting to fulfill them head-on, guaranteeing its relevance in the future.

Final thought

To conclude, litho printing, with its rich background and clinical intricacies, holds a considerable area in the print market. As the guide discloses, it's a synthesis of art and innovation, with contemporary innovations guaranteeing its significance. The industry deals with you could try this out difficulties that call for cutting-edge remedies, with a focus on automation and sustainability. The future of litho printing pivots on its capacity to adjust to these transforming demands, verifying its enduring worth in a developing market.